- rayping@pmisteel.com

- +86 139 2823 4834

- +86 139 2726 3132

Menu

Menu

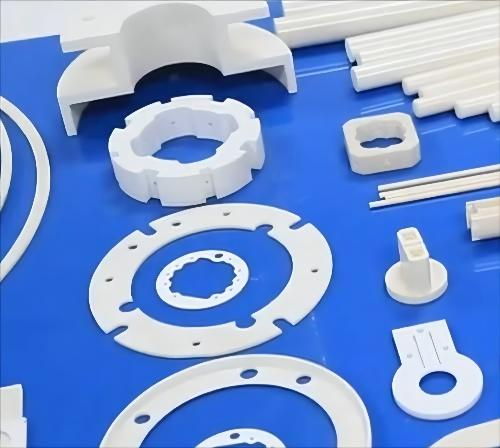

Alumina Ceramic Parts

- Home /

- Products /

- Glass industry /Alumina Ceramic Parts

96 Alumina a high purity alumina ceramic with excellent mechanical, electrical, thermal, and chemical properties, benefiting from the following features:

Typical applications

Wear ceramic parts: Ceramic Nozzles, Ceramic, Sprayers Cyclones, Homogenising devices, Ceramic Linings, Milling Systems,

Ceramic Thread guides – Precision components: Ceramic Measuring Components, Ceramic Control systems, (Micro) dosing valves,

Electronic Components (electrical inductors, switches), Mechatronics.

| Aluminas | |||||||

| Property | ASTM Method | Units | AL74 74% | AL95 95% | AL96 96% | AL98 98% | |

| General | Crystal Size (Average) | Thin Section | Microns | 13 | 11 | 8 | 7 |

| Color | — | — | White | Ivory | White Or Purple | White | |

| Gas Permeability | — | Atms-Cc/Sec | Gas Tight <10-10 | Gas Tight <10-10 | Gas Tight <10-10 | Gas Tight <10-10 | |

| Water Absorption | C 20-97 | % | 0 | 0 | 0 | 0 | |

| Mechanical | Density | C 20-97 | G/Cc | 3.03 | 3.65 | 3.71 | |

| Hardness | Vickers 500gm | GPa (Kg/Mm2) | 10.5 (1075) | 11.5 (1175) | 12.7 (1300) | 12.7 (1300) | |

| Hardness | — | R45N | 78 | 79 | 81 | 81 | |

| Fracture Toughness | Notched Beam | MPam1/2 | 2 – 5 | 3 – 4 | 4 – 5 | 4 – 5 | |

| Flexural Strength (MOR) (3 Point) @ RT |

F417-87 | MPa (Psi X 103 | 241 (35) | 310 (45) | 358 (52) | 393 (57) | |

| Tensile Strength @ RT | — | MPa (Psi X 103) | 117 (17) | 151 (22) | 200 (29) | 221 (32) | |

| Compressive Strength @ RT | — | MPa (Psi X 103) | 1378 (200) | 1827 (265) | 2068 (300) | 2241 (325) | |

| Elastic Modulus | C848 | GPa (Psi X 106) | 172 (25) | 303 (44) | 310 (45) | 345 (50) | |

| Poisson’s Ratio | C848 | — | 0.22 | 0.22 | 0.22 | 0.23 | |

| Thermal | C.T.E. 25 – 100° C | C 372-96 | X 10-6/C | 5.5 | 6.1 | 6.0 | 6.2 |

| C.T.E. 25 – 300° C | C 372-96 | X 10-6/C | 5.8 | 7.0 | 6.8 | 6.8 | |

| C.T.E. 25 – 600° C | C 372-96 | X 10-6/C | 6.3 | 7.7 | 7.5 | 7.6 | |

| Thermal Conductivity @ RT | C 408 | W/M K | 4 | 19 | 23 | 29 | |

| Max Use Temp | — | Fahrenheit (°F) | 2800 | 3000 | 3100 | 3100 | |

| — | Celsius (°C) | 1540 | 1650 | 1700 | 1700 | ||

| Electrical | Dielectric Strength (.125″ Thick) | D 149-97A | V/Mil | 225 | 250 | 250 | 260 |

| Dielectric Constant @ 1 MHz | D 150-98 | — | 7.0 | 9.0 | 9.1 | 9.5 | |

| Dielectric Constant | D 2520-95 | — | — | 9.2 | 9.1 | 9.4 | |

| @ Gigahertz | D 2520-95 | — | — | 11.0 | 10.9 | 9.8 | |

| Dielectric Loss @ 1 MHz | D 150-98 | — | 0.0012 | 0.0006 | 0.0004 | 0.0006 | |

| Dielectric Loss | D 2520-95 | — | — | 0.0009 | 0.0007 | 0.0005 | |

| @ Gigahertz | D 2520-95 | — | — | 12.5 | 10.9 | 9.8 | |

| Volume Resistivity, 25°C | D 257 | Ohms-Cm | < 1 X 1013 | > 1 X 1014 | > 1 X 1014 | > 1 X 1014 | |

| Volume Resistivity, 300°C | D 1829 | Ohms-Cm | 4 X 1010 | 5 X 1012 | 3 X 1012 | 8 X 1011 | |

| Volume Resistivity, 500°C | D 1829 | Ohms-Cm | 3 X 107 | 3 X 109 | 7 X 109 | 2 X 109 | |

| Volume Resistivity, 700°C | D 1829 | Ohms-Cm | 2 X 106 | 3 X 108 | 4 X 108 | 2 X 108 | |