- rayping@pmisteel.com

- +86 139 2823 4834

- +86 139 2726 3132

Menu

Menu

| UNS Number | N07718 |

|---|---|

| Werkstoff Number | 2.4668 |

Inconel 718 is a special type of high-strength superalloy with a nickel-chrome base that makes it resistant to corrosion, high pressure and extreme temperatures of up to 700°C.

Inconel 718 is a nickel-based super alloy that is well suited for applications requiring high strength in temperature ranges from cryogenic up to 1400°F. Inconel 718 also exhibits excellent tensile and impact strength.

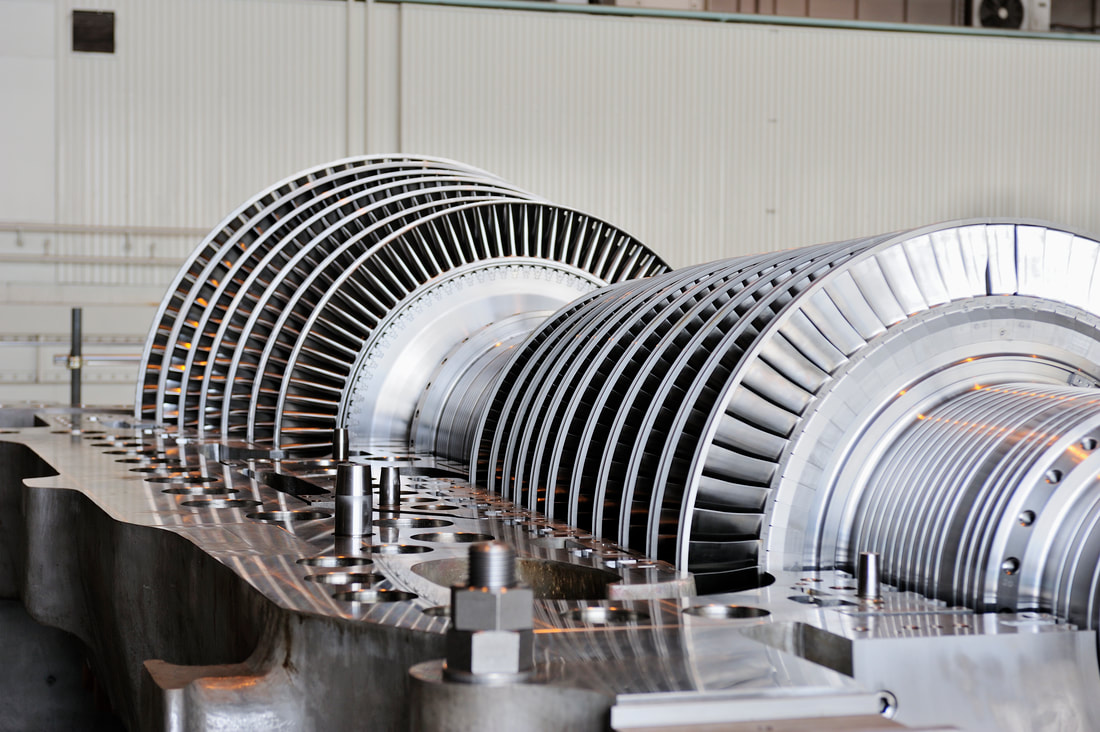

Inconel 718 has been increasingly applied in commercial engines from the late 1960’s, specifically as the disc and rear frame material in gas turbines. Beyond these original and still major high temperature applications, it is also being used as a generic alloy in nuclear, oil and gas industries and cryogenic structures due to its excellent strength and aqueous corrosion resistance at ambient and low temperature.

Generally, Inconel 718 is the most widely used superalloy, accounting for about 35 % of all superalloy production, and over 50 % of the superalloy content in some engines.

Inconel 718 can be used in a variety of applications including:

| Chemical Components | Fe | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | Ti | Nb | B | Co | Al | |

| Minimum | Ba | – | – | – | – | – | 17 | 50 | – | 2.8 | 0.65 | 0.5 | – | – | 0.2 | Nb+Ta:

4.75~5.5 |

| Maximum | 0.08 | 0.35 | 0.35 | 0.015 | 0.015 | 21 | 55 | 0.3 | 3.3 | 1.15 | 2.5 | 0.006 | 1 | 0.8 |

| Tensile Strength σb Mpa |

Yield Point σs Mpa |

Elongation δ % |

Section Shrinkage

ψ % |

Hardness

HBW |

| ≥1275 | ≥1035 | ≥12 | ≥15 | 331~444 |

| Product Form | Size Range From | Size Range To |

| Sheet & Plate | 0.30 mm | 25 mm |

| Round Bar | 4 mm | 380 mm |

| Tube | 6 mm | 260 mm |