- rayping@pmisteel.com

- +86 139 2823 4834

- +86 139 2726 3132

Menu

Menu

| UNS Number | N02200/N02201 |

|---|---|

| Werkstoff Number | 2.4060/2.4061 |

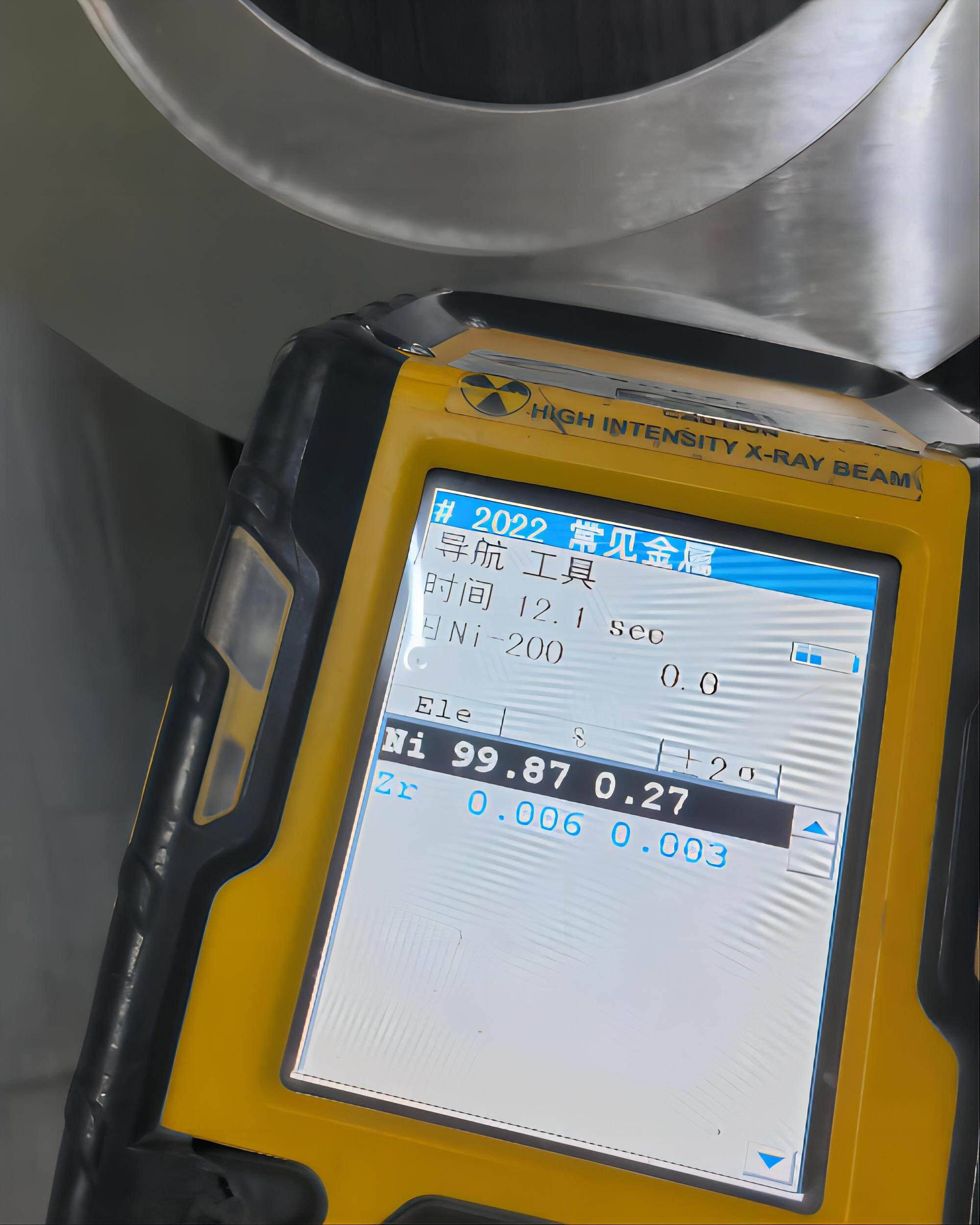

Nickel Alloy 200 is a solid solution strengthened, commercially pure wrought materials with excellent mechanical properties and resistance to corrosion. It also has exceptional resistance to caustic alkalis at different concentrations and temperatures. However, the corrosion resistance is better in de-aerated acid. The alloy has low gas content and vapor pressure, and high thermal and electrical conductivities. Alloy 200 can be shaped through all hot working and cold working practices. The alloy can be hot worked between 649°C (1200°F) and 1232°C (2250°F), with heavy forming carried out at temperatures above 871°C (1600°F). Annealing is performed at temperature between 704°C (1300°F) and 871°C (1600°F).

Nickel Alloy 201 alloy is a commercially pure wrought alloy having properties similar to that of nickel 200 alloy, but with a lower carbon content to avoid embrittlement by inter-granular carbon at high temperatures. It is resistant to acids and alkalis, and dry gases at room temperature. It is also resistant to mineral acids depending on the temperature and concentration of the solution.

Typical applications

| Alloy Grade | Chemical Components | C | Si | Mn | Fe | S | Ni | Cu |

| Nickel 200 | Minimum | – | – | – | – | – | 99 | – |

| Maximum | 0.15 | 0.35 | 0.35 | 0.4 | 0.01 | – | 0.25 | |

| Nickel 201 | Minimum | – | – | – | – | – | 99 | – |

| Maximum | 0.02 | 0.35 | 0.35 | 0.4 | 0.01 | – | 0.25 |

| Alloy Grade | Tensile Strength

σb Mpa |

Yield Point

σs Mpa |

Elongation

δ % |

Hardness

HBW |

| Nickel 200 / 201 | 345-485 | 83-240 | long.

35-60 |

75-100 |

| Product Form | Size Range From | Size Range To | Standard |

| Sheet & Plate | 0.30 mm | 25 mm | ASTM B 162/ ASME SB 162, DIN 17750, ISO 6208, BS 3072-3073 (NA12), SAE AMS 5553, |

| Round Bar | 4 mm | 380 mm | ASTM B 160/ ASME SB 160, DIN 17752, ISO 9723, VdTÜV 345. |

| Tube | 6 mm | 260 mm | ASTM B 161/ ASME SB161, B 163/ SB 163, B 725/ SB 725, B730/ SB 730, B 751/ SB 751, B775/SB 775, B 829/ SB 829, DIN 17751, ISO 6207, BS 3074 |