- rayping@pmisteel.com

- +86 139 2823 4834

- +86 139 2726 3132

Menu

Menu

Stainless Steel 904L

- Home /

- Products /

- Stainless Steel /Stainless Steel 904L

| UNS Number | N08904 |

|---|---|

| Werkstoff Number | 1.4539 |

Stainless steel 904L (UNS N08904) is a super austenitic stainless steel with very low carbon content that is designed for moderate to high corrosion resistance in a wide range of process environments.

The high nickel (25%) and molybdenum (4.5%) contents of the stainless steel 904L provide good resistance to chloride stress corrosion cracking, although not total resistance as judged by the extremely severe laboratory test, boiling magnesium chloride. The Chromium, molybdenum and nickel levels provide general and chloride pitting corrosion resistance above the level of Types 316 and 317 in many media. The copper addition provides added resistance to reducing media such as hot phosphoric acid and dilute sulfuric acid.

Stainless steel 904L has been incorporated in ASTM and ASME specifications, and is widely and readily available in a variety of product forms, welding electrodes, and fittings. The 904L has performed well in a variety of service environments such as utility scrubbers, acid and fertilizer production.

Some of the major applications of stainless steel 904L including:

| Chemical Components | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| Minimum | – | – | – | – | – | 19 | 24 | 4 | – | 1.2 |

| Maximum | 0.02 | 0.7 | 2 | 0.03 | 0.01 | 21 | 26 | 5 | 0.15 | 2 |

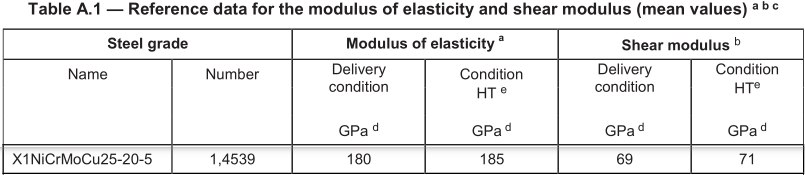

| Elastic Modulus | Coefficient of Thermal Expansion (CTE) | Coefficient of Thermal Conductivity | Specific Heat Capacity | Resistivity | Magnetism | |||||||||

| 20°C | 100°C | 200°C | 300°C | 400°C | 500°C | 100°C | 200°C | 300°C | 400°C | 500°C | 20°C | 20°C | 20°C | |

| GPa | 10-6K-1 | W/m.K | J/kg.K | Ω.mm2/m | ||||||||||

| 195 | 190 | 182 | 174 | 166 | 158 | 15.8 | 16.1 | 16.5 | 16.9 | 17.3 | 12 | 450 | 1 | no* |

*-Small amounts of ferrite and/or martensite caused by cold deformation will increase the magnetizability.

| Product Form | Size Range From | Size Range To |

| Sheet & Plate | 0.30 mm | 25 mm |

| Round Bar | 4 mm | 380 mm |

| Tube | 6 mm | 260 mm |